Solvent welding (gluing PVC pipes) in cold weather presents challenges that must be counterbalanced. Why? Pipe and fittings take longer to soften in colder weather. Cold pipe is also more resistant to solvent attack, so softening it with an aggressive primer is important during cold weather.

By following certain instructions when gluing PVC pipe in cold weather and demonstrating patience, you can successfully solvent weld pipe joints in sub-zero temperatures (as low as -15°F).

We’re sharing eight tips to ensure successful solvent-cemented pipe joints during the cold winter months.

1. Prefabricate as much of the piping system as possible in a warm environment.

We recommend assembling as much of the piping system as possible in a heated work environment. If you can control the temperature, it'll make for better joints.

Any joints made at the assembly work site should be protected by some sort of temporary or portable shelter.

2. Choose the best PVC cement for cold weather

Choosing the best PVC cement for cold weather will ensure the durability and reliability of your plumbing or piping projects. Cold weather can significantly affect the performance of PVC cement, as lower temperatures can slow down the curing process, potentially leading to weaker joints that are more susceptible to leaks and failures.

One highly recommended product for cold weather applications is Oatey All Weather Medium PVC Cement. This cement is specially formulated to work effectively in a wide range of temperatures, from as low as -15°F to a high of 110°F. Its medium-bodied consistency allows easy application and a strong bond, even in challenging weather conditions.

The benefits of using Oatey All Weather Medium PVC Cement include its fast-setting properties, which ensure quick curing and reduce the risk of joint failure. Additionally, it is suitable for use on all schedules and classes of PVC pipe and fittings up to 6 inches in diameter, making it a versatile choice for various projects.

Read this case study to learn more about using Oatey All Weather in cold weather applications. It discusses Victor Trentacost, a New Jersey plumbing company owner who successfully used Oatey All Weather Medium PVC Cement for a new construction project during cold weather. He replaced his regular cement with this all-weather solution to handle low temperatures, ensuring strong, reliable joints. Trentacost's project included extensive PVC piping, which passed inspection and met the project timeline, demonstrating the cement’s effectiveness in cold conditions.

Another excellent low-temperature PVC glue option is the Oatey FlowGuard Gold 1-Step Yellow Cement, designed for use specifically with FlowGuard Gold CPVC pipe and fittings. The one-step application process eliminates the need for primer while providing a strong, reliable bond in cold weather conditions, and simplifying the installation and saving time.

In addition, the cement’s bright yellow color makes it easy to identify, ensuring proper application. The Oatey FlowGuard Gold 1-Step Yellow Cement offers high strength and durability, ensuring your joints remain secure and leak-free even in colder temperatures.

Watch this video to learn how to correctly solvent weld with Oatey products, and check out our blog on How to Achieve a Perfect Solvent Cement Joint Every Time.

3. Store cement and primers in a warmer area.

Colder applications require storing your pipe cement in a warmer environment (above 40°F). It’s important not to leave solvent cement outside in the cold for an extended period because it will take on a gel-like consistency. If the cement has gelled, we do not recommend using it. Solvent cement should remain fluid.

If you have bulk items on the job site, store them in a temperature-controlled area so they do not come in contact with the cold.

Maybe you keep your cement and primers on your truck dashboard while you're traveling between job sites. If you've been out for a couple of hours, we recommend bringing them inside after your last service call. That way, the product can get acclimated to the warmer temperature and reach the right consistency for your next project.

4. Remove moisture from pipe ends and surfaces.

Before starting the solvent welding process, take time to clean off pipe ends and fittings to remove any dampness, residual water or ice. Moisture penetrating the cement will cause it to gel.

Of course, wet or damp conditions are sometimes unavoidable. In that case, we recommend using a solvent cement formulated to cure in damp conditions, such as Oatey Rain-R-Shine, a fast-set cement designed for wet conditions.

5. Aggressively apply primer to fittings and pipe.

Particularly in colder applications, be sure to apply and aggressively work in primer to create a solvent weld on PVC and CPVC pipes. Oatey Purple Primer is an NSF-listed primer for use on all schedules and classes of PVC and CPVC pipe and fittings.

To understand the importance of applying primer, think of the fitting and the pipe as your skin. Your pores are coated and closed tightly; working the primer more aggressively onto the fitting and the pipe will ensure that you open up their pores. That way, you are preparing the pipe to accept the cement.

While applying primer to fittings and pipes, be sure to re-dip between each application.

Once you have primed the pipe and the fitting, apply the cement and finish the connection within five minutes. Waiting too long will allow the primer to evaporate and negatively affect the creation of a good solvent weld.

6. Vigorously shake or stir cement before usage.

Before every application, we recommend shaking the can or stirring its contents. This will help blend the cement components, ensuring an even consistency throughout.

7. Allow a longer cure time before testing or using the system.

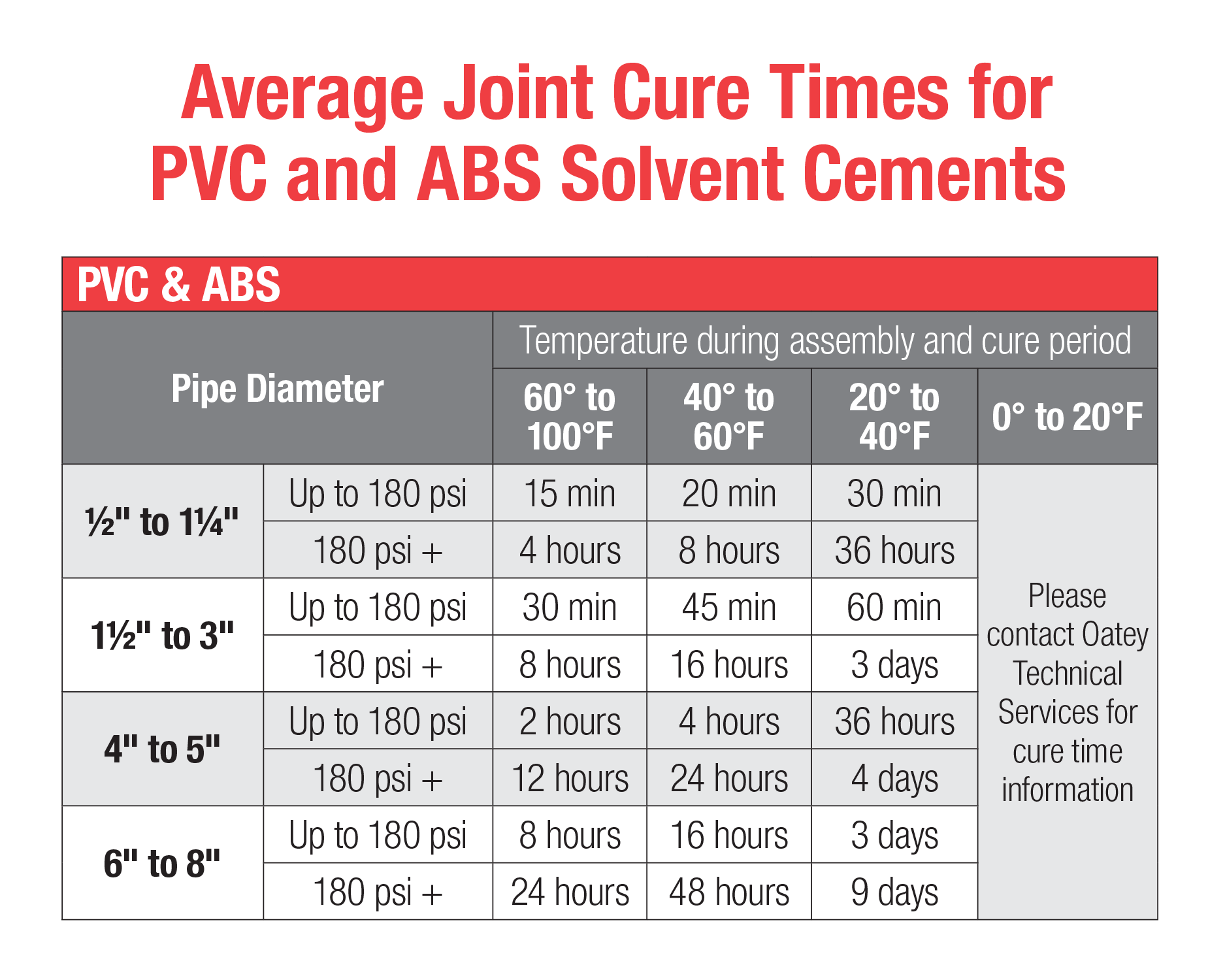

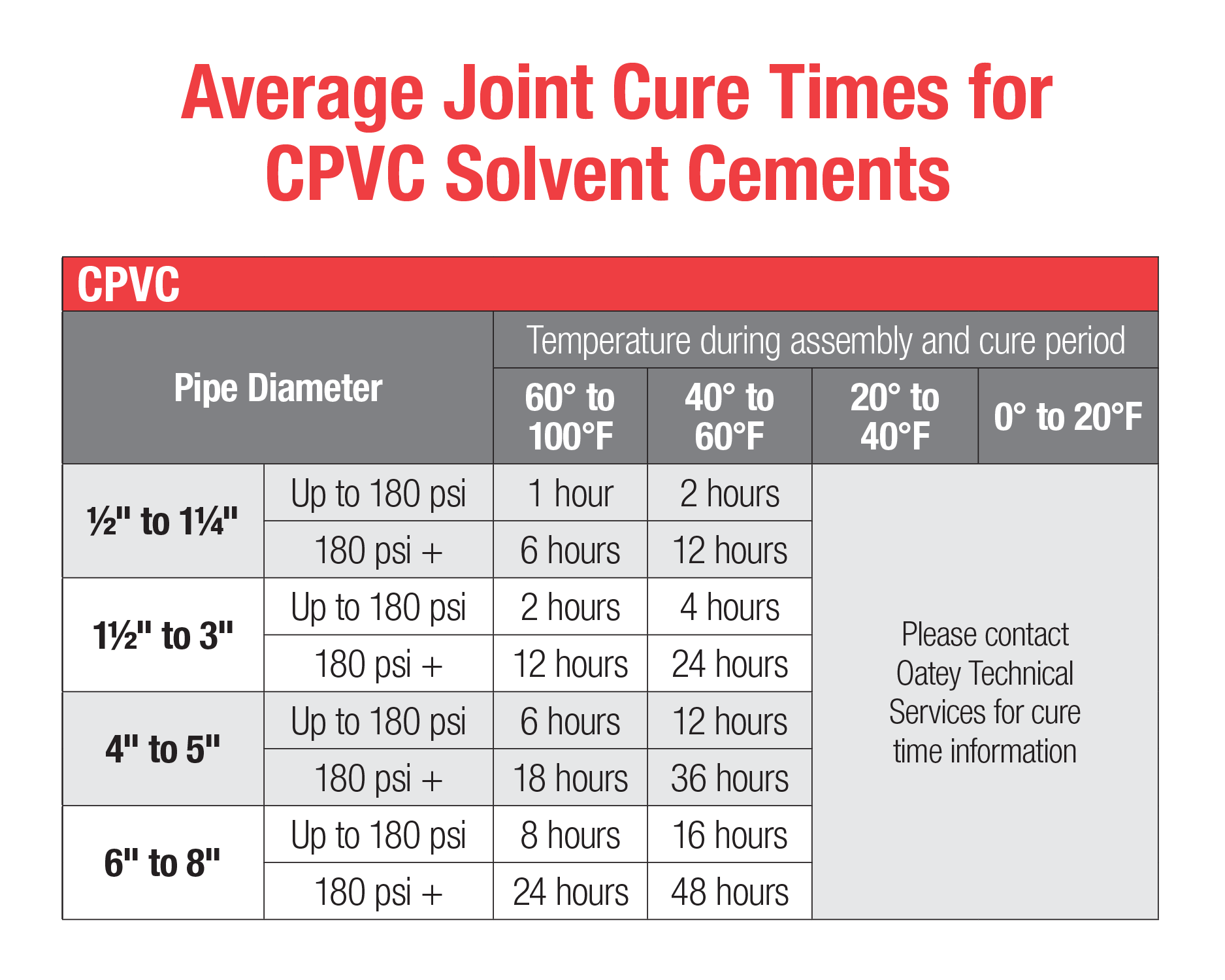

How long does Oatey cement take to dry? Cure time depends on pipe material and size, ambient temperature and humidity. As noted, solvent cement will take longer to cure in colder temperatures. Allow enough time for the solvents to evaporate before testing the system or putting it into service.

In temperatures between 20°F to 40°F, the joint may take up to three days to fully cure for higher pressure applications. However, refer to the average joint cure times provided by the PVC, ABS, and CPVC solvent cement manufacturers. For temperatures below 20°F, we recommend contacting Oatey Technical Services for exact cure time information.

Do not attempt to speed up the cure time by applying direct heat to the joint. Doing so could deteriorate joint strength or affect the pipe's integrity.

However, you can create a temperature-controlled environment to accelerate the process. If you have a temporarily heated area, you may close off the dwelling's openings to help speed the process while leaving your pipe ends open so that airflow can enter the system and help the solvents evaporate.

View ouroverview document for more information on all our cement offerings and their cure/set times.

8. Follow all ASTM standards and steps.

It's essential to follow all ASTM standards and steps in the solvent welding process. When preparing the pipe, do not skip any, such as choosing not to chamfer it.

If you don't chamfer the pipe or bevel the outside edge, the sharp edges can scrape the cement off the fitting walls as the pipe is inserted. This could cause blockage or leak paths.

In colder temperatures, it is essential not to skip these steps because — once again — the cold makes creating a solvent-welded joint more challenging. To ensure you follow all ASTM standards and create a perfect solvent weld, avoid these five common solvent welding mistakes.

With our application tips for cold-weather solvent welding, you can create long-lasting, leak-free connections this winter.