Loud, "banging" pipes – a customer complaint that professional plumbers know all too well. And if left untreated, all that banging can have serious implications that result in complex plumbing system issues.

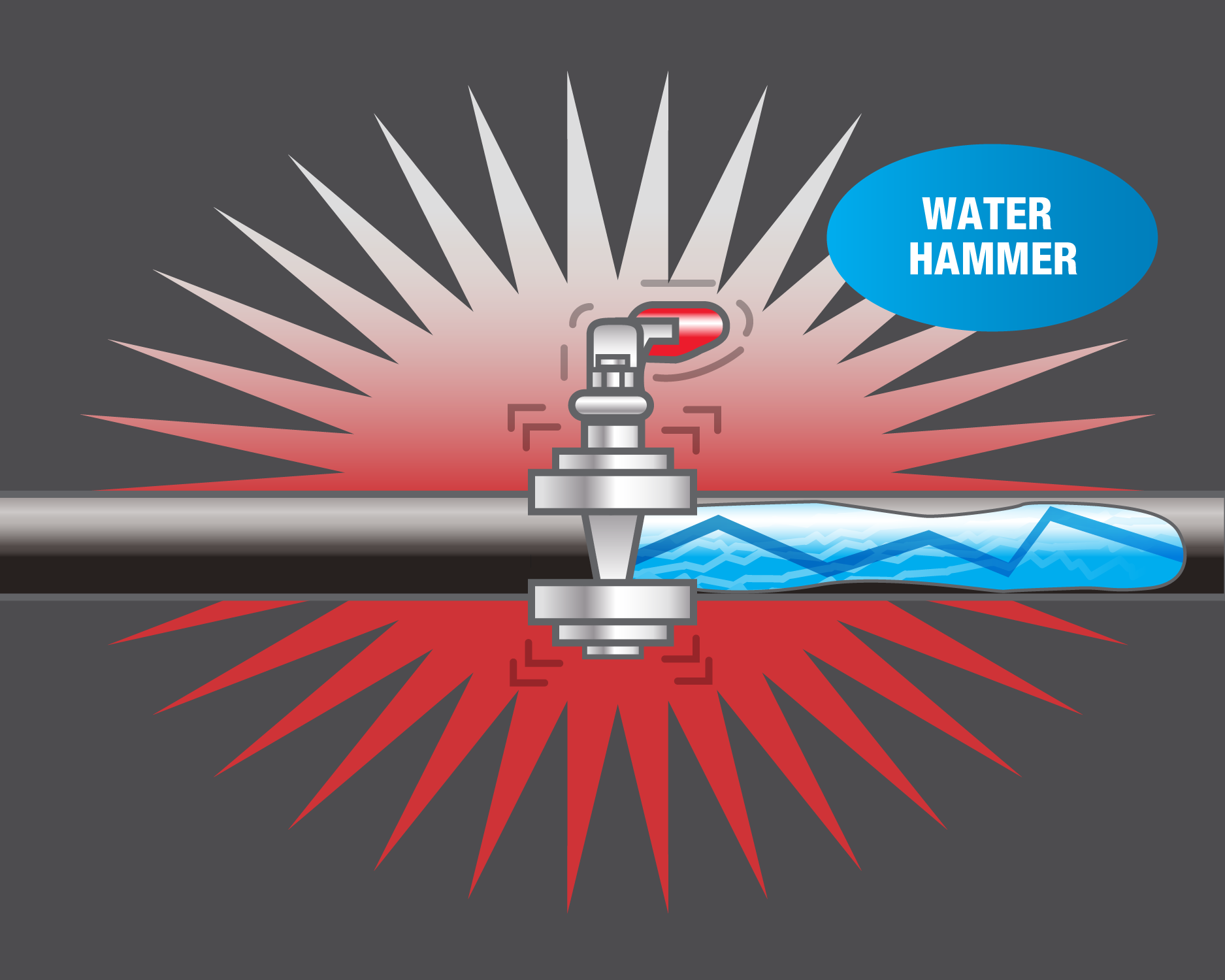

Pipes that bang and clang can be caused by water hammers, which can lead to potential damage to fixtures, valves, and seals and can even cause dripping water. Water hammer can occur in both hot and cold water pipes.

Fortunately, there are ways to prevent water hammer and keep pipes silent. In this blog, we’ll discuss what plumbing professionals should know about water hammer, including how to stop pipes from banging for good.

What Is Water Hammer?

Water hammer, also known as hydraulic shock, is a phenomenon that occurs when water in motion is suddenly stopped or changes direction. This sudden stop or directional change causes a pressure surge or shock wave that travels through the pipes, causing the banging sound commonly associated with water hammer. Various factors, including closed valves, water pressure changes, and loose pipes, can cause water hammer.

Are Banging Water Pipes Dangerous?

Banging pipes are not life-threatening, but they can lead to serious problems for a plumbing system, resulting in significant costs and inconvenience. While the problem may seem like a minor annoyance, the constant banging can cause damage to fixtures, valves, and seals, leading to leaks and other issues.

Additionally, water hammer can cause stress on plumbing pipes, leading to cracks or breaks. Left unchecked, these problems can also lead to costly repairs and even flooding.

Where Is Water Hammer Common?

Water hammer damage typically occurs in specific areas of your plumbing system. Key locations include spaces with high water pressure, fast-closing valves, and long pipe runs, including:

- household appliances, such as dishwashers and washing machines — especially high-efficiency models with quick-closing solenoid valves.

- toilets and faucets due to their rapid shut-off valves.

Areas with high municipal water pressure entering a building are more prone to water hammer. Due to the high velocity at which water travels through the system, the rapid closure of a valve can produce a sudden change of motion and transfer energy throughout the system, putting extreme stress on joints and directional fittings.

For these reasons, a system's incoming pressure should be evaluated to ensure it does not exceed 80 pounds per square inch (psi). If it does, a pressure-reducing valve (PRV) should be installed to reduce the possibility of water hammer damage.

Hammer arrestors should be used in conjunction with PRVs in these types of high-pressure areas; likewise, where there is frequent opening and closing of valves: shower diverters, washing machines, dishwashers, and sensor-operated valves.

Why Assess Visible Water Lines?

While water hammer is audible, the sound may be deceiving and not pinpoint the issue's exact location; e.g., washing machine location. The sound may appear to be coming from the valve area but could result from an unsecured pipe within the wall cavity. Once a water hammer sound is verified, check for unsecured or loose supply lines or pipes making contact with a finished surface.

Water hammer can be absorbed by any of these unsecured lines, resulting in partial to extreme movement — creating contact with adjacent surfaces. Pipes should be properly supported and insulated to prevent them from touching surrounding building materials. Pipes that are not adequately secured will move and cause a knocking or vibrating sound when coupled with even the slightest amount of water hammer.

Locate any internal or external holes that water lines pass through to see whether these lines touch the sides of the hole in any direction when gently pushed. Any water line that passes through a hole should have a support installed or expandable foam applied. Both can also keep pests and insects from traveling through a hole. A combination of a j-hook and foam pipe insulation wrap on large holes in wood plates can cushion them against any wood or drywall.

For new installations of water distribution systems, check with your local building officials to ensure individual lines are properly secured and insulated to reduce the possibility of water hammer.

How to Fix Banging Water Pipes

In the past, plumbers were required to install a 12-in. capped vertical riser (air chamber) on a fixture(s) supply run to dead-end the line. As the system filled, this riser would fill with displaced air and create an air chamber.

But soon after putting the system into service, plumbers discovered that the air within this chamber had been replaced by water. The only way to restore the hammer protection was to drain and refill the system continuously.

This inconvenient practice led us to the modern-day water hammer arrestor.

What is a Water Hammer Arrestor?

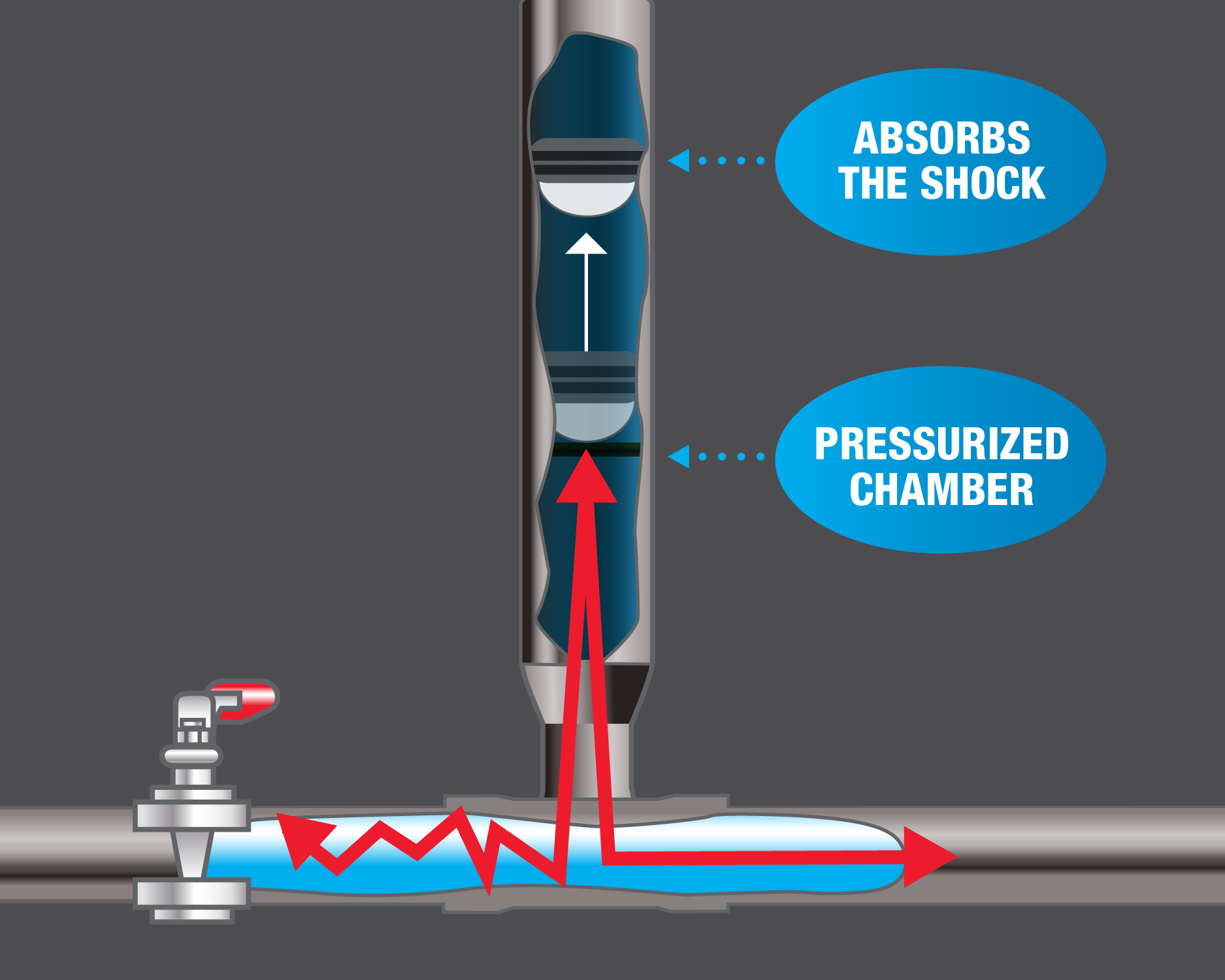

A water hammer arrestor is installed in your plumbing system to prevent water hammer. The device features a pressurized sealed air chamber that can be installed at any angle to absorb the shock of a quick-closing valve. The arrestor then releases the pressure back into the system with the assistance of an internal piston.

The internal piston creates a watertight/airtight seal to avoid any air loss and prevent the chamber from filling with water. This helps keep your pipes quiet and prevents potential damage.

Water hammer arrestors come in various sizes and can be installed in various locations, including washing machines, toilets, and other fixtures. Installing water hammer arrestors is an easy and effective way to prevent water hammer and maintain your plumbing system in top condition.

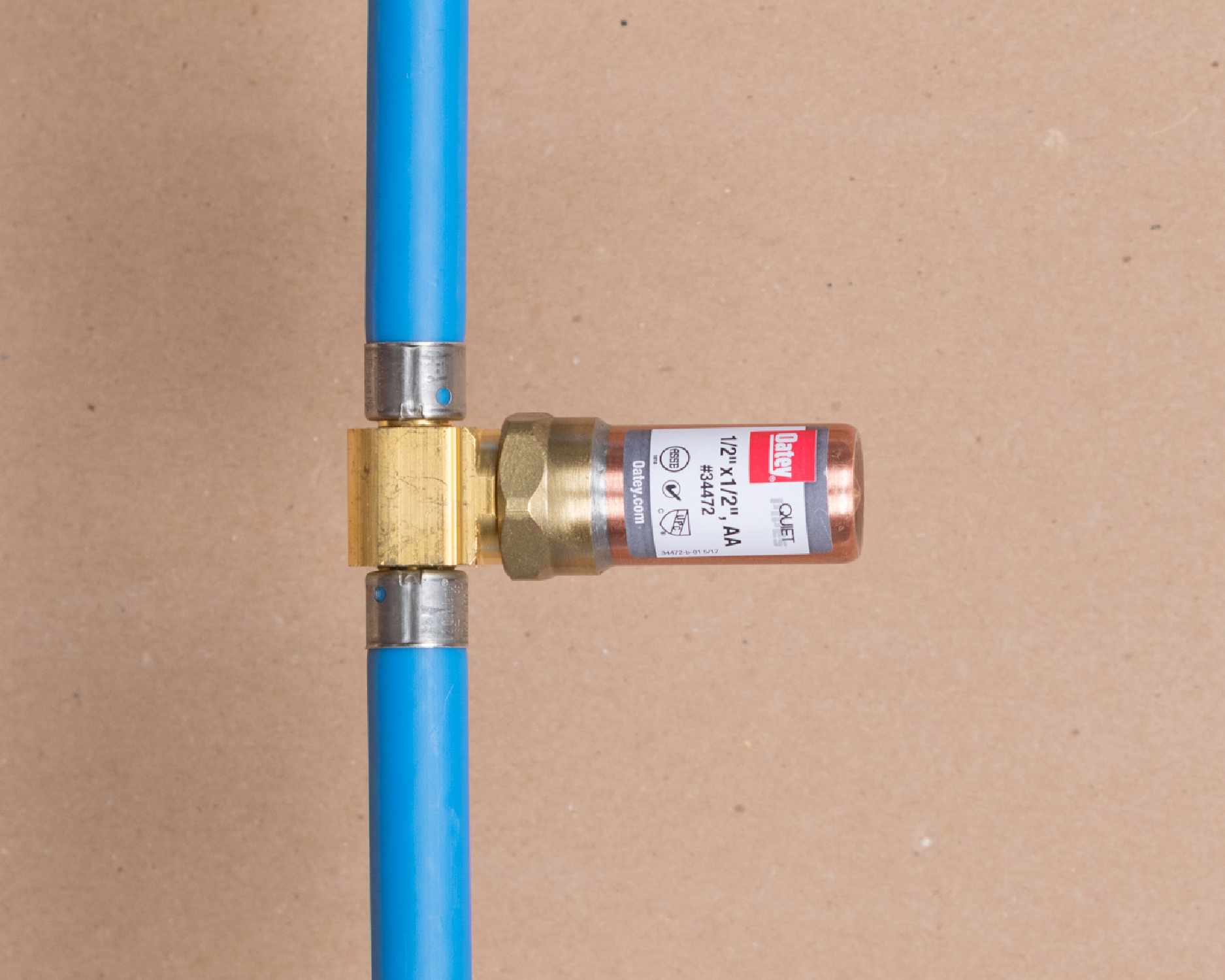

Oatey® Quiet Pipes® Hammer Arrestors are designed to relieve current and potential water hammer problems in residential and commercial applications. Oatey offers a wide variety of connection options, saving plumbers time by eliminating the need for costly transition joints. The arrestors carry a limited warranty equal to the lifetime of the plumbing system they are installed in.

Quiet Pipes water hammer arrestors are available in sizes AA and A through F to protect any residential or commercial application, as well as for different connection types, including:

- Straight connections

- CPVC (male or female)

- Copper sweat of press

- PEX 1807 (crimp) and F1960 (cold expansion)

- MIP (male iron pipe)

- Tee connections

- PEX

- Compression (in a variety of connection options)

- ⅞-inch hose bibb connections

Check out this video to learn more about Oatey Quiet Pipes Hammer Arrestors.

Silence Banging Water Pipes with Oatey Quiet Pipes Water Hammer Arrestors

Water hammer arrestors for washing machines

Adding to the versatility of Quiet Pipes Water Hammer Arrestors, the Oatey® Quiet Pipes® Washing Machine Supply Line Shock Absorber resembles a 90-degree angle or a small 'T,' making it perfect for water hammer arrestor applications with washing machines.

These arrestors come equipped with two hose connections: (1) a female hose connection that screws directly onto either the valve or the back of the washer; and (2) a male hose connection at the bottom of the arrestor for the hose to screw onto. This design allows installation from the supply box to the washer or vice versa, providing flexibility based on accessibility and installer preference.

As mentioned previously, high-efficiency washing machines, notably the newer models, are often more prone to causing water hammer. The mechanics behind this are not entirely clear, but it is likely associated with the washer valves, which close faster or more frequently than their counterparts in older models. That’s why it is not uncommon for homeowners who never had issues with water hammer to experience problems immediately after upgrading to a high-efficiency washer.

Oatey tip: One practical idea to reduce water hammer in washing machines involves the hoses, which are usually left hanging loosely between the washing machine and the wall or the box valve. This positioning can cause water hammer when the hoses flop around during the closing of the valve.

Securing these hoses — for example, by zip-tying them together and then to a pipe or something sturdy — can help eliminate water hammer. While these hoses are flexible and, therefore, challenging to secure, this simple preventative measure can effectively reduce water hammer and potential damage to a piping system.

Where to Install Water Hammer Arrestors?

To determine the proper arrestor size and point of installation, first consider the distance from the horizontal branch line and the fixture units. According to the IPC, “a fixture unit is a measure of the probable hydraulic demand on the water supply by various types of plumbing fixtures used to size water piping systems.”

The water supply fixture-unit value for a particular fixture depends on (1) its volume rate of supply, (2) the time duration of a single supply operation, and (3) the average time between successive operations.

In large, commercial water distribution systems, water hammer arrestors should be installed at the end of a vertical branch line between the last two fixtures served at a distance up to 20 feet from the horizontal branch line. (Always check with the mechanical engineer to confirm that additional protection is not required for your application.)

For point-of-use applications, many municipalities require the use of arrestors near any quick-closing valves, such as dishwashers, washing machines and ice makers.

Other Considerations

To prevent future piping damage, failure and leaks, incorporate hammer arrestors into a plumbing design blueprint early on.

Proper sizing and placement of hammer arrestors are equally crucial; otherwise, they cannot perform correctly or achieve longevity. Incorrectly sizing a hammer arrestor by miscalculating fixture units or failing to follow a manufacturer’s installation recommendations could end up doing little to remedy a water hammer problem.