When it comes to roof installations, you may first think of shingles and tiles as a primary component. However, roof flashing also plays a vital role in ensuring the integrity and longevity of a building’s roof.

What Is Roof Flashing? Roof flashing is used to seal some sort of roof penetration. Whether from a vent pipe, an exhaust fan, a skylight, or a chimney, roof flashings will seal and weatherproof a particular area.

Why is Roof Flashing Important? Made from durable flashing materials such as metal, rubber, or plastic to withstand harsh weather conditions and resist corrosion, roof flashings create a watertight barrier and effectively redirect water away from vulnerable areas, preventing potential roof leaks and damage to the building’s roofing structure, insulation, and interior.

Roof flashing is essential in any roofing system and should be carefully designed and properly installed by plumbing professionals or roofing contractors to ensure long-lasting protection. Understanding the different types of roof flashings can mean the difference between a dry home and costly water damage.

Fun fact: In 1947, Oatey established its first manufacturing plant and corporate headquarters on Berea Road. The first product made there was a roof flashing.

What Are The Different Types of Roof Flashings?

Oatey flashings are engineered to withstand demanding conditions. Rated up to continuous heat resistance of 180° Fahrenheit, Oatey roof flashings are suitable for Type B Installations, giving users peace of mind regarding performance and durability.

Note: Type B installations require careful consideration of safety measures and specialized flashing installation techniques.

In addition to standard flashings, Oatey also offers specialty items designed to meet specific needs. The Master Flash is an excellent choice for commercial applications, while Side and Solar Flashings provide tailored solutions for unique situations.

Below is a breakdown of the different types of roof flashings offered by Oatey:

Standard Flashings

Standard roof flashings are typically made from durable flashing materials like metal, rubber, or plastic. They are chosen for their ability to prevent water infiltration and resist corrosion even in harsh weather conditions.

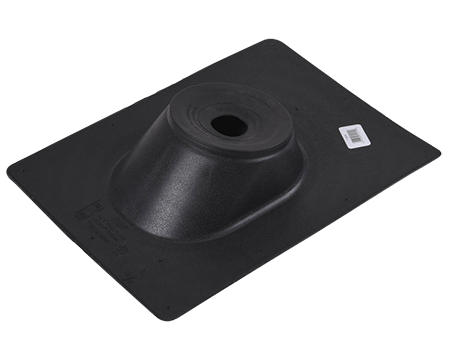

- Vent pipe flashing seals the area around plumbing vent pipes that protrude through the roof. They help prevent water from entering the roof and maintain the roofing system's integrity. Vent pipe flashings are often made of flexible materials such as rubber or thermoplastic, allowing for easy installation and flexibility in accommodating various pipe diameters.

- Multi-size flashings are specifically designed to accommodate round plumbing pipe penetrations. The appeal of using a multi-size flashing is that one flashing can cover multiple sizes, meaning an installer does not need to know the exact size they are working with. Currently, Oatey offers 1.5-inch, 2-inch, and 3-inch sizes in one flashing and 3-inch and 4-inch in another.

With adjustable features or multiple sizing options, these flashings can be easily customized to fit different penetration diameters, ensuring a watertight seal and preventing leaks. Their versatility makes them a popular choice for residential and commercial roofing projects.

- Colored flashings are an increasingly popular option for a seamless and uniform appearance. Available in a wide range of colors and finishes, these flashings can be matched to the color of the roofing material or the trim, providing a cohesive and polished look that enhances a building’s overall value and curb appeal.

Electrical Mast Flashings

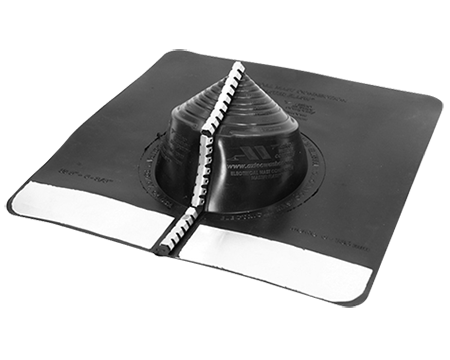

Electrical mast flashings are specialized components used in roofing systems to provide a weatherproof seal around the electrical service entrance mast. The electrical mast is the pipe or conduit that carries electrical wires from the utility service to the building. Given its vertical position and potential for water penetration, it is crucial to properly seal around the mast to prevent roof leaks and water damage.

Oatey Electric Mast Connection Master Flash® roof flashing features quick installation time for a long-term fit in a roofing electrical application.

Electrical mast flashings are designed to fit snugly around the mast and create a watertight barrier, ensuring no moisture enters the building. These flashings are typically made from durable materials, such as aluminum or EPDM rubber, with excellent weathering and UV-exposure resistance.

Roof Flashings for Metal Roofs

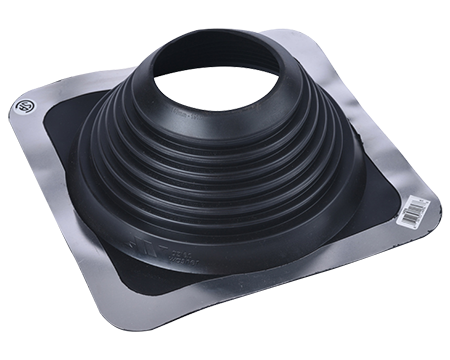

Flashings for metal roofs are specifically designed to work with the unique properties of metal, which can expand and contract with changes in temperature and weather conditions. Oatey Master Flash Roof Flashings are intended for metal-profiled roofs and can be installed on most type of roofing surface.

These flashings are made from durable materials that offer excellent resistance to corrosion and weathering. Available in different shapes and sizes, metal roof flashings are tailored to the specific requirements of each roofing project.

Side (Vertical) Flashings

Side flashings are explicitly designed for vertical installation through outside walls and ensure a proper seal and prevent water intrusion. Oatey Sideflash Vertical Flashings feature a rigid plastic panel with an elastomeric collar that seals around the pipe. They are designed to be installed under the house wrap or building paper to become part of the building envelope.

Specialty Flashings

Specialty roof flashings, such as breather vents and frost-proof flashings, offer unique features and benefits that address specific roofing challenges.

- Solar flashings are specialized components used to integrate solar panels seamlessly into the roof and ensure a watertight seal. They enable homeowners to enjoy peace of mind and energy savings. As solar energy becomes increasingly popular, this reliable and efficient solution protects the roof’s integrity even while supporting the weight of a panel installation.

- Oatey Aurora No-Calk Solar Aluminum Flashings are designed for commercial and residential applications requiring a watertight seal for roof penetrations around the piping for solar mounting systems.

Rain Collars

Rain collars are a vital component and are usually made from durable materials, providing excellent weathering and UV exposure resistance.

Rain collars for no-caulk roof flashing are available in various sizes to accommodate different pipe sizes. They ensure a proper fit that prevents leaks and water damage. Easy to install, they are used to repair existing flashings without affecting the roof shingles.

What to Consider When Choosing a Flashing

Different roof types require different flashings; for example, a chimney flashing may differ from a skylight flashing, depending on the structure. On the other hand, because the installation process and compatibility differ, a metal roof requires a master flashing.

Check out our video on selecting roof flashings: How to Select Roof Flashings

Below are three essential factors that drive roof flashing selection:

1. Determine the Pipe Size

Knowing the pipe diameter will allow you to choose the flashing size. Oatey offers a variety of flashing collars for every pipe diameter. Additionally, Oatey flashing collars require no cutting and easily slide over pipes. While this may seem like a minor consideration, it is essential to choose the appropriate size to avoid any complications during the installation.

2. Determine Roof Pitch

Aside from aesthetics, roof pitch determines the suitable flashing. Most standard shingle roof flashings are designed to accommodate roof pitches of up to 45 degrees. The pitch is often indicated by terms like “10/12” or “12/12,” indicating the angle of the roof. For example, a 12/12 pitch means that for every 12 inches of horizontal distance, there is a 12-inch vertical rise, resulting in a 45-degree angle.

If the roof pitch exceeds 45 degrees, a high-riser flashing is recommended. It allows for a greater angle, ensuring a proper seal despite the steeper slope.

Appropriate flashing for the specific roof pitch is vital to avoid unnecessary stress on the rubber collar. Over time, excessive pressure on the flashing can weaken its effectiveness and potentially lead to water seepage.

3. Choose the Base Size of the Flashing

The governing code typically drives the flashing base size, so check with your local jurisdiction. Oatey offers a variety of base sizes to meet specific needs.

4. Choose Flashing Material Type

Oatey offers a variety of base materials: aluminum, copper, galvanized steel, and plastic. The choice is mainly based on personal preference and aesthetics. Many people select the material based on shingle color to blend the flashing seamlessly into the roof. Others prefer a durable plastic base that is flexible enough to put in their pockets before installation.

5. Determine Any Other Factors

It is essential to recognize other factors that may impact flashing choices. These factors include temperature, UV exposure, and proximity to a saltwater source. As noted, Oatey offers flashings for every scenario: side flashings, solar flashings, or master flashings for metal roofs.

With an understanding of the importance of roof flashings in protecting your home from water damage and the many types of flashings available, you can make an informed choice and safeguard your home and investment for years to come.

To learn how to install roof flashing properly, check out our blog, How to Install a Roof Flashing.