PTFE (polytetrafluoroethylene) tape, also known as plumbers tape, is wrapped on a pipe to help create a leakproof seal between the threaded joint of a male pipe and a female fitting.

Thread sealant is used in many industries for various applications requiring a watertight and airtight seal. It is simple to use, yet many professional installers insist there's only one "correct" way to use it. We're here to give our expert advice on the topic.

In this blog, we'll review everything you need to know about thread sealant tapes — from deciding which tape to use to how to apply it. By the time you're done reading, you will be a full-fledged expert on plumber's tape!

What do you need to know before choosing a tape?

There are a variety of tapes on the market today. Each one has its benefits and features. When selecting which tape to use, you'll base it on the pipe's width, the application's color, and the chemical compatibility of whatever is running through the line. Oatey plumber's tape comes in various colors, widths, thicknesses, and densities.

Colors are visual identifiers to show a person what flows through a piping system. For instance, yellow thread sealant tape is required by most municipalities when assembling a gas piping system. General-purpose tapes are usually white or gray, making them more aesthetically pleasing when used on similarly colored pipe materials.

Widths include ½", ¾", and 1". A ½" tape would be ideal for a smaller diameter pipe. When assembling larger diameter pipes, a ¾" or 1" width would be best because it provides better coverage on the threaded section of the pipe.

Thickness is usually referred to by mil. Higher mil thickness reduces the number of full wraps necessary to create a watertight or airtight seal.

Density refers to the pipe's ability to compact into the threads' root. Tapes higher in density prevent excess stretching during assembly, leading to less compaction and possible leak paths.

Let's look at the most popular thread sealant tapes offered by Oatey:

General-purpose PTFE tape

Our PTFE tapes provide exceptional versatility and can be used on all threaded pipes, valves and fittings carrying acids, solvents, alkalis, steam, hot and cold water, LP gas, natural gas, oxygen, and almost any chemical. They are weather-resistant, flexible, non-hardening, nontoxic, non-stick and non-flammable.

- Color: gray

- Width: ¾ in, ½ in, 1 in

- Thickness: 3.5 mils thick

- Density: high, 0.70 - 1.00 grams/cubic centimeter

- Color: white

- Width: ¾ in, ½ in, 1 in

- Thickness: 3 mils thick

- Density: 0.35 – 0.45 grams/cubic centimeter

Oatey® PTFE White General Purpose Thread Seal Tape

- Color: white

- Width: ¾ in, ½ in

- Thickness: 3 mils thick

- Density: 0.7 grams/cubic centimeter

- Color: white

- Width: ¾ in, ½ in, 1 in

- Thickness: 3 mils thick

- Density: low, 0.35 – 0.45 grams/cubic centimeter

- Color: light gray

- Width: ¾ in, ½ in, 1 in

- Thickness: 3.5mil Thick

- Density: 0.7 - 1.00 grams/cubic centimeters

- Color: white

- Width: ¾ in to ½ in

- Thickness: 3.5 mil thick

- Density: high, 1.0 - 1.3 g/cc

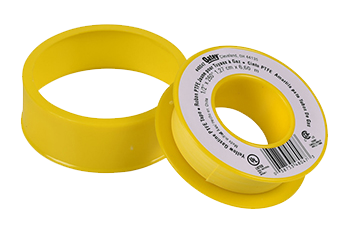

Yellow gas line tape

Designed and manufactured for natural gas, propane, butane, water, oil and chemical lines, this yellow thread sealant tape meets all gas company standards worldwide and seals threads quickly and easily.

Harvey™ Yellow Gas Line PTFE Thread Seal Tape

- Color: yellow

- Width: ½ in

- Thickness: 4 mils thick

- Density: 1.35 - 1.50 grams/cubic centimeters

Oatey® Yellow Gas Line PTFE Thread Seal Tape

- Color: yellow

- Width: ½ in

- Thickness: 4 mils thick

- Density: 1.35 - 1.50 grams/cubic centimeters

Water Pink

Commonly used by pipefitters and plumbers, pink thread sealant tape signifies you are handling piping for water lines, sewage lines and sprinkler systems. This tape is very heavy-duty compared with standard-type tape.

Oatey® PTFE Pink Water Line Thread Seal Tape

- Color: pink

- Width: ½ in

- Thickness: 3 mils thick

- Density: 135-150 grams/cubic centimeter

Please refer to our website to check compatibility and view our line of thread sealants.

Tips for proper wrapping

- First, apply tape only to the male threads.

- To ensure a good seal, wrap the tape in a clockwise direction and cover the threads completely.

- You need to use only two or three wraps of tape; however, thinner tape may need four or five wraps.

- Beware of excess tape-wraps. Anything extra will get pushed out of the joint.

- Pull the roll, and the tape will snap for you easily.

- Since there are no cure times for plumbers tape, you can thread your pipe immediately after taping.

For those who learn best by watching others, check out this video to learn the proper way to apply PTFE thread sealant tape.

Cautions when using

Before applying any plumbers tape, we recommend checking to ensure your system — including whatever material was used to make it or can be found in it — is approved and compatible with the thread. You can find that information on the thread sealant container or check with the manufacturer.

Make sure all your pipe threads are clean. You'll want your joints free from rust, scale, grease, and other contaminants. Remove any debris with a clean cloth or wire brush.

FAQs

What is the maximum pipe size you can use thread tape on?

There are no limitations on the diameter of the pipe. However, it would be best if you wrapped the tape around the male threads enough to fill the fixture (female threads).

When should I use pipe dope and thread tape?

At Oatey, we recommend any pipe sizes over 1¼" with pressure and fluids moving through it should have the male threads wrapped with tape. Then spread the approved pipe joint compound spread over the tape.

How do I apply pipe thread tape? Are all the tapes used the same way?

Whatever the width of the tape, the application remains the same. After selecting the properly sized tape for your thread, you will wrap it clockwise while keeping the tape at the bottom.

For ½", ¾" and 1" pipe threads, you will need to wrap the threads in a straight pattern only three to five times around the male thread if the tape width is the same size as the pipe diameter. For 1¼" pipe threads and above or when tape width is smaller than pipe size, you will wrap four to five times, starting at the end of threads and working up.

Is Oatey White General Purpose thread seal tape safe on natural gas lines?

Yes! All Oatey thread sealant tapes will work on natural gas lines. Oatey does, however, recommend using yellow gas line thread tape with PTFE on all natural gas line installations. The Oatey yellow gas line thread tape is approved by code for this application, and as we noted previously, the yellow color is a visual identifier that the correct tape was used in the application.

Knowing how to wrap PTFE tape correctly and deciding which kind to use for your plumbing project is the key to a stress-free installation. Oatey is here to help you achieve and maintain a watertight and airtight seal between pipes every time.

Contact our Technical Department for any questions regarding your project at technical@oatey.com.