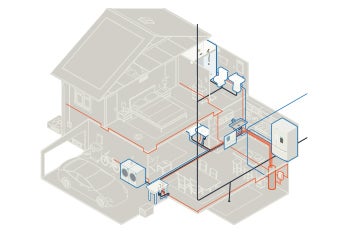

The behind-the-wall framework of a home contains a vital plumbing system that keeps your home running efficiently and safely. Within every residential plumbing system you have subsystems that include water-supply pipes, drain pipes, vent pipes and gas lines.

Each subsystem acts as a key component in the complexity of water supply, waste removal, and more. With a plethora of piping options, the following breakdown can help you determine the best options for your home or next project.

Water supply system options

The water coming into the home (potable water) – either from your well or from your public utility company (water purveyor) – is called the water supply.

From your master bathroom shower to the basement toilet, your water supply system circulates water throughout your home efficiently by the touch of a button or a simple turn of a handle. A structure of pipes, ranging from ¼” to 1 ¼”-inches in diameter, supports the distribution of this water.

Let's look at the types of piping responsible for routing your water supply.

- Copper: Commonly used within a home, copper pipe offers a lightweight portability that can be easily transported to and within a home. With their high thermal conductivity and durability, copper pipes provide long-term reliability to homeowners.

This durable metal contains formable properties that allow the pipe to bend and form to your liking; however, when copper tubing requires connection, you can easily solder these pipes. Oatey's line of solder, flux, and cleaning products for copper applications provide the confidence you need in creating a secure bond between metal workpieces.

Although the properties of copper pipe offer some corrosion resistance, corrosion can manifest over an extended period of time. Conduct annual inspections to locate any leaks that can occur over time and avoid corrosion-related health hazards.

Copper sizing options range from ½ inch to 2-inches. For residential applications, the most commonly used copper pipe is Type L.

- PEX (plastic): Cross-linked polyethylene, or PEX, pipe, has gained popularity over the past three decades among professionals, DIYers and homeowners. Why? Fewer pipe connections and the installation labor and potential leaks they involve. This flexible plastic material can bend around corners and through walls and floors, connecting to a PEX manifold that is itself connected to the main water supply, thereby eliminating the need to make a pipe connection every time there is a change in direction.

PEX is also corrosion-resistant and can expand, offering resistance to cracks as temperatures drop to freezing. Often is marked with a lacquer finish — colored red or blue — to distinguish between hot and cold supply lines, PEX can be connected to existing metal supply lines using the appropriate fittings, eliminating the need for soldering completely.

PEX pipe and fittings range from ¼-inch to 1 ¼”-inch copper tube size (CTS) in both inches and metric diameters, with hydrostatic pressure ratings of 160 pounds per square inch at 73°F and 100 psi at 180°F.

- CPVC (plastic): Chlorinated Polyvinyl Chloride, or CPVC, contains properties resistant to corrosion and damage by highly chlorinated domestic water. This lightweight thermoplastic material can withstand temperatures up to 200°F. Anything above this temperature will cause the pipe to soften and your plumbing system to fail.

The chlorine present in CPVC prevents bacteria from forming within the pipe before the water enters your home. It offers superior mechanical strength in residential water systems, effortlessly connecting with other pipes and fittings with easy use of solvent cement, like Oatey's CPVC cement.

CPVC sizing options range from ½-inch to 1 ¼”-inch copper tube size (CTS) and pipe sizes from ½ to 2-inch, with hydrostatic pressure ratings of 400psi at 73°F and 100psi at 180°F.

- Galvanized: Commonly installed in homes built before 1960, galvanized pipes made of steel were dipped in protective zinc to prevent corrosion. Less costly than copper, galvanized pipes contain wider diameters, allowing higher flow rates through it.

Hard water contains calcium carbonate that, when combined with zinc carbonate, forms a protective layer resilient to corrosion. However, the life expectancy of galvanized pipes decreases with extended use over time as the layer deteriorates, causing impending failure of your water system.

Soft water does not contain calcium carbonate leaving the zinc layer susceptible to corrosion. As this type of water passes through the pipe, it damages the protective zinc layer, leaving the steel vulnerable to corrosion and rust. This shortens the lifespan of the pipes over a shorter period of time than hard water.

For these reasons, we recommend that you replace galvanized pipes with one of the above options to ensure your home water system functions optimally and is free from health hazards.

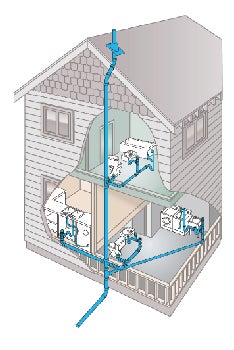

Drain-waste-vent system options

Plumbing Drain-Waste-Vent systems, or DWV, consist of two types of pipe: 1) drain pipes that provide a network for the removal of waste from various fixtures; and 2) vent pipes that remove and prevent unwanted gas from escaping inside the building. Vent pipes also maintain the necessary balance of pressure to allow water to flow.

The DWV system uses gravity and air displacement throughout the piping network to properly function and “breathe.” In a simplified example, think about the tiny holes on a to-go coffee cup lid that allow air into the container. Without proper air flow, there wouldn’t be enough air displacement in the cup for the liquid to flow out evenly, making it very difficult to sip. In short, for the liquid to come out, air must come in.

All DWV plumbing systems require at least one vent penetration through a home’s roof line. This penetration allows air to enter the system, while also permitting sewer gas to escape. To prevent blockages, pipes in a DWV system are larger in diameter than supply pipes: 1-¼ inches to 4 inches.

Let's dive deep into the intricate DWV piping network to see what kind of pipes keep this crucial system efficient.

- PVC: Polyvinyl chloride piping offers cost efficiencies due to its flexibility, durability, and ease-of-installation features. PVC also resists corrosion from acids, bases, salts, and oxidants.

Studies have shown that this low-carbon plastic piping has a lower failure rate than other pipes. Use products such as the Hercules® PVC Purple Primer and Multi-Purpose PVC Clear Cement to prime and cement connections to keep potential plumbing failures at bay.

Although this type of pipe may look similar to white, Schedule 40 PVC pipe and fittings, DWV PVC pipe cannot handle pressure. DWV systems make use of gravity to relieve significant stress on the PVC.

- ABS: Acrylonitrile Butadiene Styrene contains a chemical called bisphenol A, or BPA, which increases durability by hardening the pipe. Unlike PVC's two-step connection process, ABS utilizes a cement such as Hercules® ABC Black Medium-Bodied Fast Set PVC Cement for an easy one-step connection.

ABS is easily distinguished by its black color. Although not as flexible as PVC, this type of pipe is stronger and resistant to cracks, tears, etc., and can withstand extremely cold temperatures. ABS is available in 10-foot and 20-foot lengths in the United States.

- Cast Iron Soil Pipe: This heavy-duty iron pipe provides several features that can make its higher price tag worth the investment. A hubless cast iron pipe, with a diameter of only four inches, can still support nearly 5,000 pounds per linear foot. Offering fireproof properties as well as low sound transmission makes cast iron the quietest in the DWV category.

The caveat? Its strength is paired with heavy weight, which can lead to sinking and cracking, as well as difficult repairs. Undiluted strong acids below pH 4.3 can cause corrosion. As waste moves through cast iron pipes, hydrogen sulfide gas creates a chemical reaction, causing deterioration within the lines.

Although still manufactured, this type of pipe is typically found in older homes.

Copper: Unlike other copper piping, DWV copper piping cannot be used in a water system. Despite its larger diameter, its walls are thinner with a maximum pressure rating of only 15 psi. This effectively limits its use to systems with little to no pressure. Like cast iron soil pipe, DWV copper is typically found in older homes.

Copper DWV pipes have distinguishable yellow markings with a wall thickness of .040 for a 1-¼" pipe.

Galvanized: As with water supply systems, galvanized pipes are commonly found in older homes. Due to corrosion over time, this steel pipe has given way to the more modern and innovative piping solutions described above.

Gas System

Gas piping systems use pressure to deliver natural gas or LP gas to your heating system. Starting at the source, natural gas flows from higher to lower pressure through a system of pipes. Before exiting this distribution system, the gas must pass through an external pressure regulator to lower the flow rate before entering your home.

The oldest and most commonly used piping option for residential gas systems is black iron pipe.

- Black iron: Black iron properties include heat resistance and durability, with a pressure rating of at least 150 psi. With its thick walls, this heavy-duty metal pipe is not easily penetrable. That gives homeowners security in knowing that pipes won't leak potentially deadly gas throughout the home.

Its malleability enables the use of screwed fittings, eliminating the need for welding. These pipes can fit together to form an airtight seal using Teflon sealant tape.

Conclusion

Now that you have been briefed on the various types of plumbing pipes used in residential plumbing systems, be mindful of external conditions that can disrupt the systems in your own home. For example, use appropriate materials to secure the piping in your home, such as supply hangers.

Just as importantly, remember that the efficiency of your water-supply, DWV, and gas systems require regular maintenance. This is the best way to maintain the longevity and optimal performance of your systems, regardless of pipe type.