< Sewer Air Test Plugs

Cherne® I-Series® Air-Loc® Plugs

Key Features & Benefits

- 24-60 in. I-Series® Air-Loc® Plug

- Designed for low pressure air testing and leak location testing

- Optimized design offers improved performance and safety

- Mechanically bonded rubber and end plates eliminate failures from chemical bonding

- Color-coded inflation ports match hose and panel for Air-Loc system

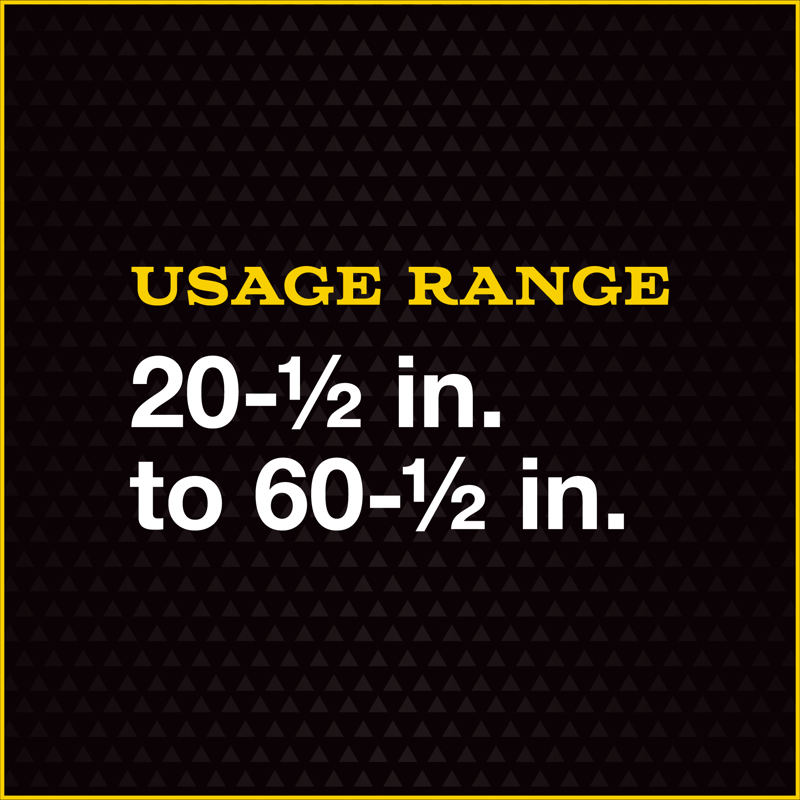

- 20-1/2 in. to 60-1/2 in. usage range

- 6 PSI maximum backpressure; 25 PSI inflation pressure

- 101 in. x 19-1/2 in. x 19-1/2 in.

- Made from tough, tear-resistant natural rubber

- Aluminum end plate minimizes rust and corrosion

- 3/4 in. eyebolts provide superior holding strength

Specifications

| Brand: | Cherne |

|---|---|

| Weight: | 136 LB |

| Nominal Size: | 24 in. - 60 in. (600 - 1500 mm) |

|---|---|

| Product Type: | Air-Loc |

| Chain Eye Bolts: | 3/4 in. |

| Inflation Pressure: | 25 psi (1,7 bar) |

| Maximum Back Pressure: | 6 psi |

| Usage Range: | 20.5 in. - 50 in. (521 - 1270 mm) |

| Deflated Diameter: | 20.77 in. |

| Deflated Length: | 88 in. (2235 mm) |

| Inflation Thread: | 0.25in. & 0.5 in. |

| Plug Type: | Blocking |

More Specifications

Frequently Asked Questions

Cherne offers a 2 year warranty on all pneumatic plugs from date of manufacture, (plugs are post-dated by six months to allow for shelf time). If kept in controlled conditions (not exposed to sunlight and kept at temperatures between 0-125 degrees F) the pneumatic plugs remain in good condition for a longer period of time. Plugs should always be inspected for visual damage prior to every use.

What type of rubber is a Cherne pneumatic plugs made from?

All of Cherne’s pneumatic pipe plugs are made from natural rubber. The only exception is our yellow pillow plugs which are made from a polyurethane impregnated fabric.

How often should a pneumatic plug pressure be checked?

Inflation pressure should be checked a minimum of once every 4 hours while a pneumatic plug is in use.