< Cements

Oatey® All Purpose Cement

Key Features & Benefits

- 8 oz. all-purpose solvent cement with dauber

- Meets ASTM Standards D2564, D2235 and F493

- For DWV, potable water and irrigation applications

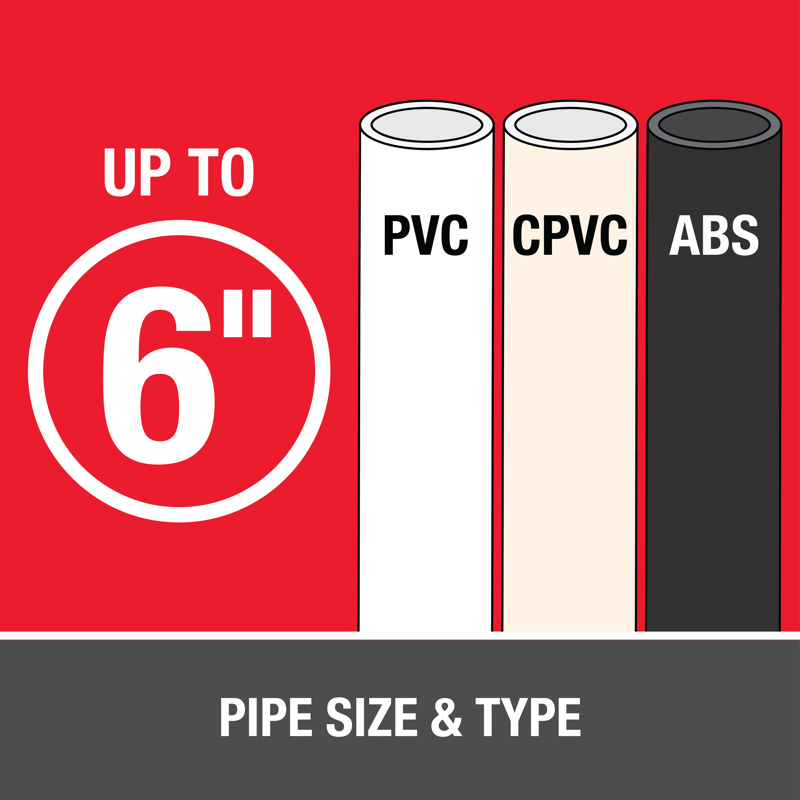

- Solvent welds ABS, PVC and CPVC pipe

- Medium viscosity easily fills gaps and provides more working time

- Recommended application temperature of 40°F to 110°F / 4°C to 43°C

- Cement appears off-white in the can but dries clear when applied in a thin film

- All Oatey solvent cement and primer products are certified to UL Greenguard Gold

- Low VOC solvent cement that meets California South Coast Air Quality Management Districts (SCAQMD) 1168/316A or BAAQMD Method 40 requirements

Specifications

| Size: | 8 oz. |

|---|---|

| Brand: | Oatey |

| California VOC Compliant: | No |

| Maximum Application Temperature °F: | 110ºF |

|---|---|

| Set Type: | Standard (40 - 110° F) |

| Set Speed: | Medium Set |

| Product Type: | All Purpose Cement |

| Maximum Application Temperature °C: | 43ºC |

| Maximum Use Temperature °F: | 140ºF |

More Specifications

Technical Resources (10)

More Downloads

Available in 5 variations

Frequently Asked Questions

Cure times vary depending on a wide variety of factors. Please review the documents below and read our blog for more helpful information.

Solvent Cement Cure Charts

Solvent Cement Instructions

What PVC cements allow for the longest set-up time, for multiple joint assemblies?

The regular body cement has the longest working time once the joint has been assembled on pipe sizes up to 4” diameter. However, the regular body cement has the quickest set up time before the joint is assembled because of the quick evaporation process. Any pipe sizes over 4” should be discussed with the technical department.

What cements allow for the shortest set-up time, for multiple joint assemblies?

The heavy duty cement has the shortest working time once the joint has been assembled on pipe sizes up to 4” diameter. However, the heavy duty cement has the slowest set up time before the joint is assembled because of the slow evaporation process. Any pipe sizes over 4” should be discussed with the technical department.