< Flange Accessories

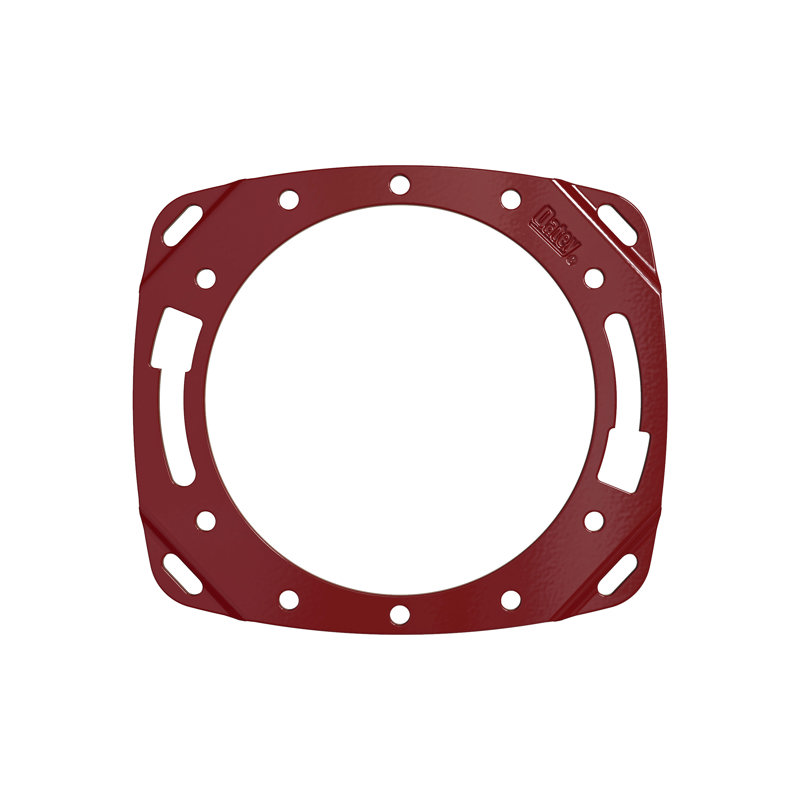

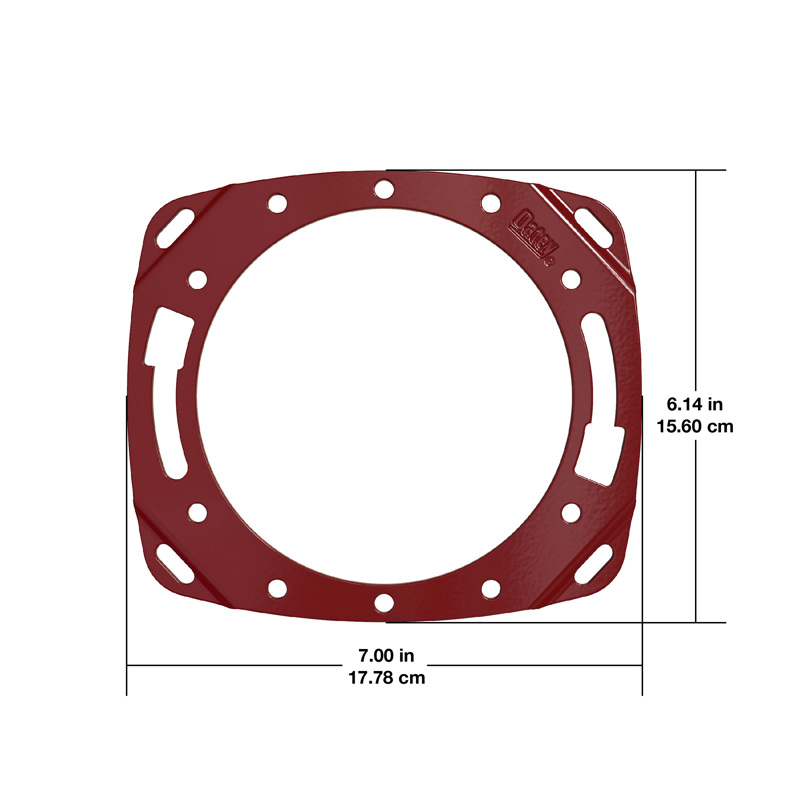

Oatey® Fix-it Flange Repair Ring

Key Features & Benefits

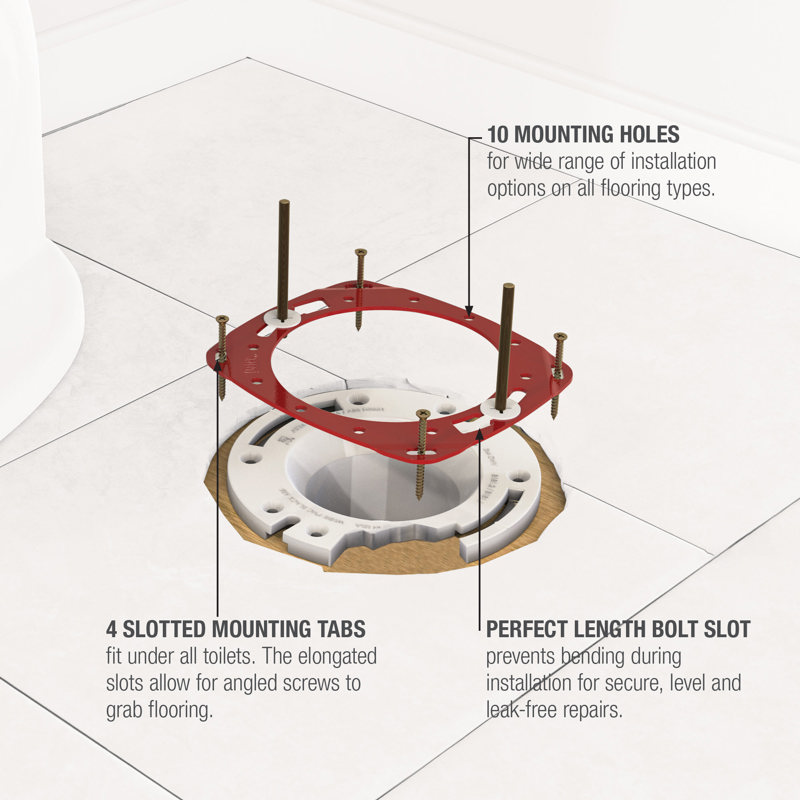

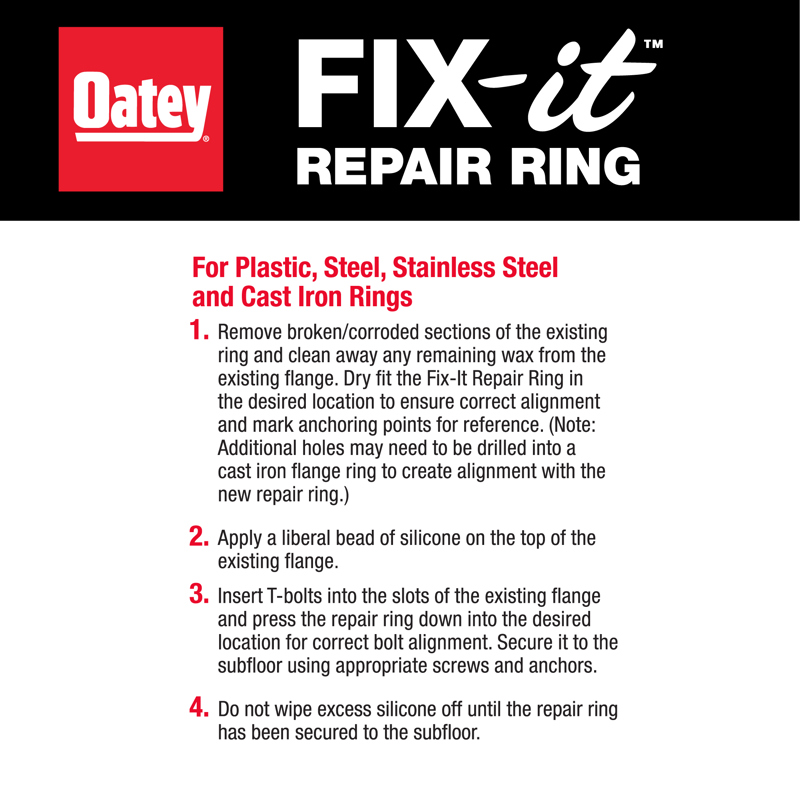

- For repairing broken, cracked or worn-out toilet flanges

- Engineered for secure connection to the floor

- Ensures the elimination of leak paths

- Adjustable after the toilet compresses on the wax

- Allows for use with both 1/4 in. and 5/16 in. T-bolts

- Features 4 slotted mounting tabs that fit under all toilets

- Elongated slots allow for angled screws to grab flooring

- Includes 10 mounting holes for a wide range of installation options

- Easy to install and user friendly

Specifications

| Brand: | Oatey |

|---|---|

| Color: | Red |

| Material: | Steel |

| Adjustable: | Yes |

| Weight: | 0.418 lb. |

More Specifications

Frequently Asked Questions

After the toilet has been removed, you must remove the existing toilet bolts and clean all the old wax off the existing toilet flange. Decide how much height is needed in order for the bottom of the top flange to be parallel with the finished floor height. You should replace the existing flange if it is broken or rusted badly; the spacer kit will not work for this application. After confirming the existing flange is in good condition, install the new extra-long toilet bolts into the flange. You can use the gaskets that come with the kit to seal between multiple PVC spacers, but 100% silicone is recommended between the top of the existing flange and the bottom of the first spacer. This will ensure that all voided areas are water tight between the transition points. After the desired height is reached, the flat washers and 1/4" nuts are threaded onto the extra-long bolts. This will compress and hold the spacers in place. It is recommended that you try and secure the new spacer or spacers to the subfloor through the four holes molded into the spacers. You can now install a wax seal and finish the toilet installation. Never use one of the seals in place of the wax seal. THE TOILET WILL LEAK WHEN FLUSHED!

Is there a flange that can be used to replace a broken or corroded cast iron flange for a toilet?

Oatey offers three styles of repair flanges for this application.

The first is the No-Caulk cast iron repair flange which comes in two depths. Once the old flange is removed and cast iron pipe is cleaned off, these flanges will slide over the vertical cast iron drain pipe. The flat side of the gasket should be facing down and resting on the inside bottom lip of the flange. Tightening the four bolts in even rotation will compress the gasket against the outside of the pipe, and create a water tight seal. Remember that the bottom of the flange must be set on top of the finished flooring, and then screwed into the subfloor.

The second is our PVC or ABS Twist-N-Set repair flange which inserts into the vertical cast iron drain pipe after the old flange is removed. The gasket tightens as the flange is turned in a clockwise rotation. Remember that the bottom of the flange must be set on top of the finished flooring, and then screwed into the subfloor.

The third option is the PVC or ABS Replacement closet repair flange which also inserts into the vertical cast iron drain pipe after the old flange is removed. This flange is sealed by the tightening of three stainless steel bolts in even rotation. This compresses the gasket between the outside of the flange tail piece, and the inside of the cast iron drain. Remember that the bottom of the flange must be set on top of the finished flooring, and then screwed into the subfloor.

All flanges must be screwed into the subfloor before setting the toilet bowl into place, this sometimes will require drilling pilot holes through the finished flooring.

When would a Closet Flange Spacer Kit be used?

The Closet Flange Spacer Kit is used when the finished floor of your bathroom is higher than the bottom of the existing toilet flange.